Rotating Drum Dryer

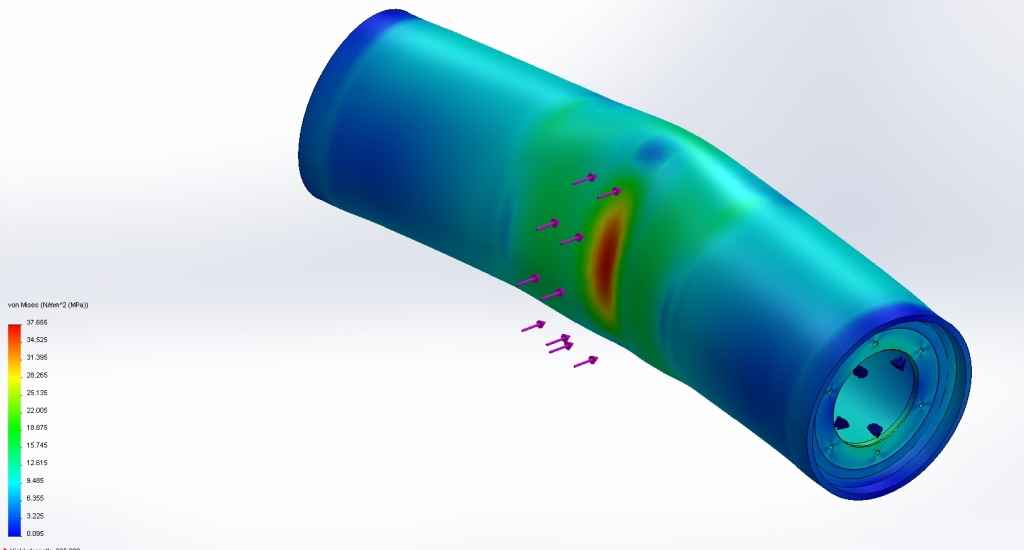

For manufacturing asphalt, Gebroeders van der Lee, awarded TME the contract for a rotary drum dryer. Here, aggregates are dried and heated for further processing. For the manufacture of asphalt, it is necessary to withdraw all moisture from the base material to ensure bonding with the bitumen.

Designed at an appropriate inclination, the drum dryer transports the aggregate through the entire drum by rotating. Flights are affixed to the interior of the rotating drum. These are fin-like structures that pick-up the material from the bed of the drum and shower it through the steam of hot air produced by an integrated burner. Efficient positioning of the flights, create an optimal “curtain” of aggregates for the highest drying efficiency.