Discharge system for subsea rock installation

Subsea rock installation plays a vital role in safeguarding against erosion and protecting subsea infrastructure such as cables and pipelines.

Van Oord has introduced the Braveness, a state-of-the-art flexible fall pipe vessel specifically designed for efficient subsea rock installation. This innovation facilitates the installation of a wide range of rock sizes necessary for this purpose.

The process begins at a quarry where rock is loaded onto the Braveness, which boasts two cargo holds with a combined storage capacity of 15500 tons. The rock can be discharged with pinpoint accuracy from the vessel onto the seabed in three configurations. First by discharging the rock through a fall pipe through the moonpool. Secondly, by discharging over the side of the vessel through the fall pipe, and third by discharging over the side of the vessel using a tremie pipe.

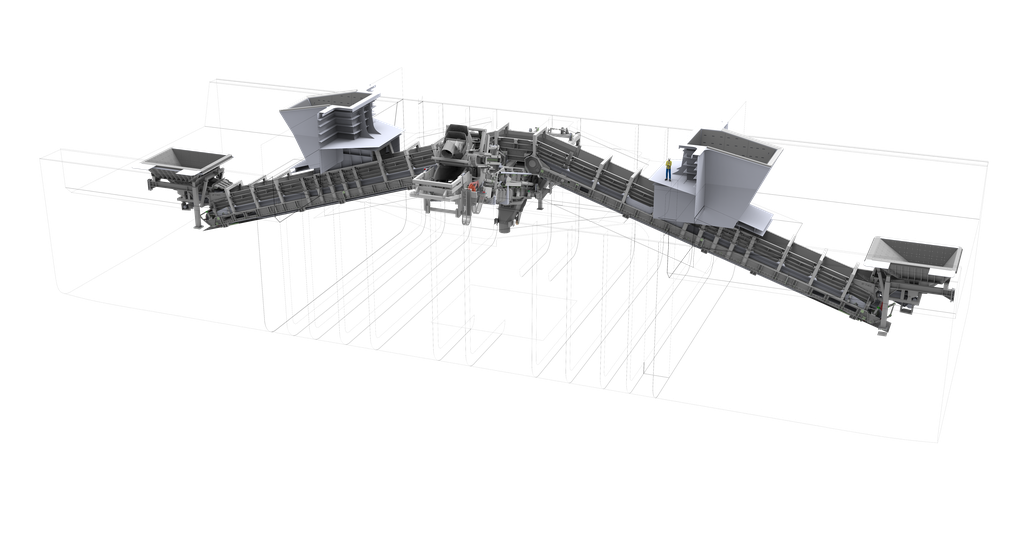

Van Oord commissioned TME to design and construct the rock transporting system for the Braveness. Two heavy-duty hydraulically driven longitudinal apron plate feeders transport the rocks from the two cargo holds into the moonpool chute and into the fallpipe. The apron plate feeders are fed by vibration feeders for the lighter rocks. Heavy rocks are picked up by an excavator fitted with a grab and loaded into a hopper which is integrated in the side skirts of the longitudinal apron plate feeders.

For discharging over the side of the vessel, the rocks are transported to the side of the vessel by a transverse apron feeder. This apron feeder is equipped with a dedicated chute depending on whether rocks are discharged via the tremie pipe or fall pipe.

The rock transporting system is designed to carry extreme loads and endure heavy wear. Extra thickness, wear resistant materials, exchangeable parts and many other measures have been taken to ensure a functional system with a long lifespan.

Key facts & figures

| Scope of work | Concept design, detailed engineering, production drawings, fabrication, project management |

| Number of apron feeders | 3 |

| Dimensions apron feeders | 30m x 2m (longitudinal conveyors) ∣ 16,5m x 2m (transverse conveyor) |

| Deadweight | 180 tonnes (2 x longitudinal conveyors) ∣ 90 tonnes (transverse conveyor) |

| Deadweight | 12.000 tonnes |

| Discharge capacity | 2.000 tonnes/hour |